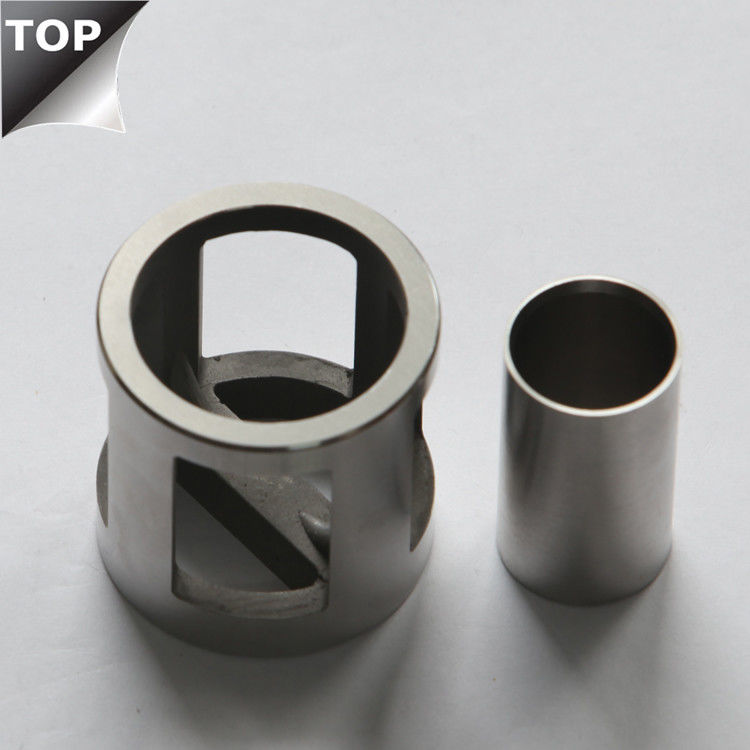

Cobalt Chrome Alloy valve seat inserts are very important parts of oil-well pump , they always show up together and cooperate very good , no better material can replace them now .

What is the Details of our Cobalt Chrome Alloy seat and ball?

| Material : |

Cobalt Chrome Alloy |

| Process : |

Casting |

| Hardness: |

38-44HRC |

| Density : |

8.4 g/cm ³ |

| Properties : |

Wear and corrosion resistance |

| Application : |

Oil well pump components , wear and corrosion resistance parts |

| Instructions : |

API standard , Drawing made upon customers request |

| Tolerance control : |

turning or grinding surface , tolerance upon drawing |

| Production lead time |

normal order 30 days |

Chemical compositions and properties (%)

| Brand |

C |

Mn |

Si |

Cr |

Ni |

Mo |

W |

Co |

Fe |

P |

S |

Density

(g/cm3)

|

Hardness

(HRC)

|

| ST 6 |

0.9-1.4 |

1.0 |

1.5 |

27-31 |

3.0 |

1.5 |

3.5-5.5 |

Bal. |

3.0 |

≤0.03 |

≤0.03 |

8.4 |

38-44 |

Dimensions of our valve seats

API Valve Seat insert Standard

| No. |

SPECIFICAIONS |

OD (inch”) |

ID (inch”) |

HEIGHT (inch”) |

| 1 |

1-1/4” |

.800” |

.940” |

1.002” |

| 2 |

1-1/2” |

.980” |

1.169” |

1.229” |

| 3 |

1-3/4” |

1.175” |

1.389” |

1.489” |

| 4 |

2” |

1.285” |

1.616” |

1.747” |

| 5 |

2-1/4” |

1.410” |

1.720” |

1.890” |

| 6 |

2-3/4” |

1.754” |

2.175” |

2.190” |

| 7 |

3-1/4” |

2.040” |

2.687” |

2.375” |

| 8 |

3-3/4” |

2.290” |

3.247” |

2.620” |

Note: The unit weight is only for reference. The actual weight might have some variations.

Chemical compositions and properties (%)

| Brand |

C |

Mn |

Si |

Cr |

Ni |

Mo |

W |

Co |

Fe |

P |

S |

Density

(g/cm3)

|

Hardness

(HRC)

|

| ST 3 |

2.0-2.7 |

1.0 |

1.0 |

29-33 |

3.0 |

|

11-14 |

Bal. |

3.0 |

≤0.03 |

≤0.03 |

8.55 |

51-55 |

| ST 6 |

0.9-1.4 |

1.0 |

1.5 |

27-31 |

3.0 |

1.5 |

3.5-5.5 |

Bal. |

3.0 |

≤0.03 |

≤0.03 |

8.35 |

38-44 |

| ST 12 |

1.1-1.7 |

1.0 |

1.0 |

28-32 |

3.0 |

|

7.0-9.5 |

Bal. |

3.0 |

≤0.03 |

≤0.03 |

8.40 |

44-49 |

| ST 20 |

2.2-3.0 |

|

2.0 |

30-34 |

3.0 |

1.0 |

14-18 |

Bal. |

3.0 |

≤0.05 |

≤0.05 |

8.65 |

53-59 |

Production process :

1. Powder metallurgy process

A. Better metallurgical structure, better strength

B. Various types of automatic pressing machines from 3 tons to 630 tons. The ordered profiles can be very flexible.

2. Investment casting process

Different volume of furnaces, the order quantity can be very flexible.

3. Machining

CNC, lathing, drilling, milling, grinding, wire cutting, polishing

Technical requirements :

Dimensions, drawings, tolerance, surface finish, radius, as your demands.

Let us know your demands, we’ll feedback you within 2 hours.

Shipment and package :

Realted products :

Product Features

1. High temperature resistance

The strength keeps stable up to 800℃ and it can even momentarily used at 1200℃.

2. Wear resistance

Due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a

CoCr alloy matrix, it has exceptional wear and galling resistance.

3. Corrosion resistance

This exellent and lovely property allows this kind of material parts to be used in oil&gas, slurry, acid liquid and any other mediums.

| For you |

| We Are |

We Have |

We Can |

| Professional Manufacuturer |

Plenty Production Capacity |

Produce Parts Meeting Customer’s Demands |

| Reputed Global Supplier |

10 years Exporting experience |

Easy Communication |

| Material Solution Expert |

Materials Science Background |

Provide Material Choice Solution |

Company introduction

Shenyang Top New Material Co., Ltd owns its advantages in the industrial metal materials area. The company specializes in the R&D, manufacturing and sales of investment casting and powder metallurgy components made of Cobalt Chrome AlloyCobalt Chrome alloy. Founded in Year 2001, SYTOP has 16 years producing experience and 10 years exporting experience. Our solid quality and integrity wins us a good name in our customers.

Why Choose us?

-Our faith is that the quality and customer's demands are always the first important thing for everyone in our company.

1. 15 years in producing cobalt alloy parts and 10 years exporting experience.

2. Providing professional solutions.

3. Our own R&D team has professional backgroun and excellent innovation ability.

4. Drawing designed ability.

5. Customized producing.

6. Small quantity is acceptable.

7. Quick feedback and good English communication.

FAQ:

Q1: Are you a manufacturer or a trading company?

A1: We are the manufacturer located in the north of China with 15 years producing experience and 10 years exporting experience.

Q2: What's the material of your bushings/sleeves?

A2: It's the CoCrW alloy, which is usually called Cobalt Chrome Alloy.

Q3: What's the Cobalt Chrome Alloy?

A3: It is a range of cobalt-chromium alloys designed for wear resistance, heat resistance and corrosion resistance.

Q4: What's the lead time of bushings?

A4: 15-35 days depending on the order quantity.

Q5: What's the tolerance and surface finish we can control?

A5: As your demand.

Q6: How do we deliver the seats?

A6: We are the VIP customer of DHL express with good discounts.

Q7: MOQ?

A7: 5pcs

Q8: Why I choose your company?

A8: We are professional. We are reliable. We are easy communication.

Your feedback is our best honor, please do not hesitate to give us your valuable feedback. Send your inquiry details in the below.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!