Product Description:

Cobalt Chrome Alloy - Product Overview

Introduction

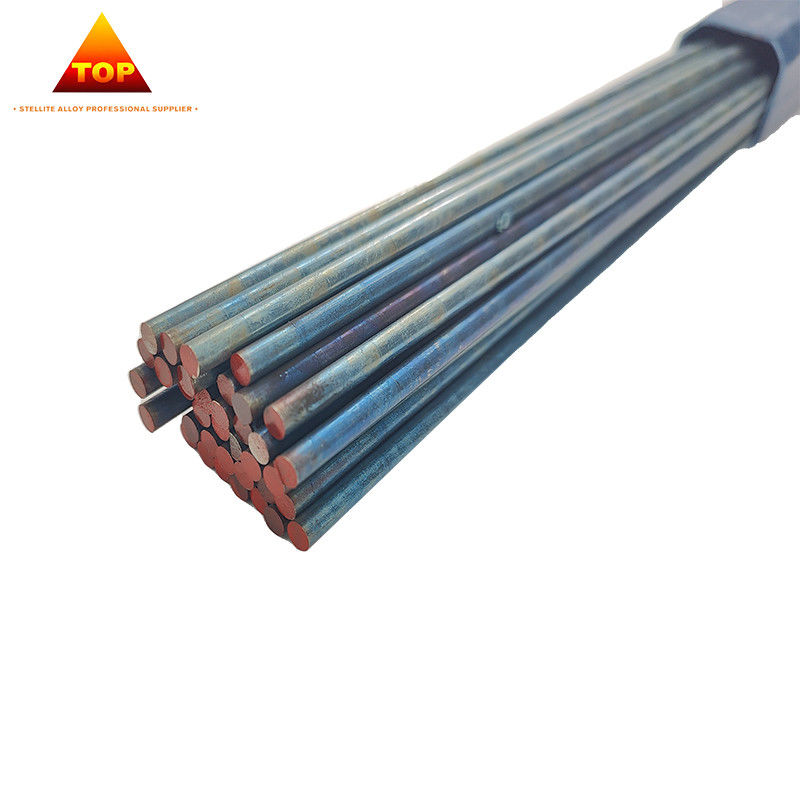

Cobalt Chrome Alloy, also known as cobalt base alloy or cobalt chromium alloy, is a versatile product that is widely used in various industries for its exceptional properties. It is a type of stellite welding electrode, which is a hardfacing rod that is used for welding and surfacing applications. The high performance of this alloy makes it a popular choice for many applications.

Properties

Cobalt Chrome Alloy is known for its excellent wear resistance, non-magnetic properties, and high hardness. It has an elongation of 20-30%, making it suitable for applications that require high strength and durability. The electrical conductivity of this alloy is 20% IACS, making it a great choice for electrical and electronic applications. It has a hardness range of HRC 50-60, which makes it one of the hardest alloys available in the market.

Applications

Due to its exceptional properties, Cobalt Chrome Alloy is used in a wide range of applications. Its high wear resistance makes it suitable for use in industries such as mining, oil and gas, and construction. It is also commonly used in the manufacturing of cutting tools, dies, and molds. Its non-magnetic properties make it an ideal choice for use in medical devices and aerospace applications. The high hardness and strength of this alloy make it suitable for use in high-temperature environments, making it a popular choice for furnace components, turbine blades, and engine parts.

Benefits

The use of Cobalt Chrome Alloy offers numerous benefits, making it a preferred choice for many industries. Its high wear resistance and hardness ensure a longer lifespan of the products, reducing maintenance and replacement costs. The non-magnetic properties make it safe for use in sensitive electronic equipment and medical devices. Its high strength and durability make it suitable for use in extreme environments, ensuring the safety and reliability of the products.

Conclusion

Cobalt Chrome Alloy is a high-performance product that offers exceptional properties and numerous benefits. Its versatility and wide range of applications make it a popular choice for various industries. Its use in welding and surfacing applications as a stellite welding electrode and hardfacing electrodes welding rod has made it a preferred choice for many manufacturers. With its outstanding properties and benefits, Cobalt Chrome Alloy is a reliable and efficient solution for all your industrial needs.

Features:

- Product Name: Cobalt Chrome Alloy

- Coefficient Of Thermal Expansion: 12.5 μm/m·K

- Elongation: 20-30%

- Material: Cobalt Chrome Alloy

- Applications: Hardfacing, Wear-resistant Components, High Temperature Components

- Surface Finish: Smooth

- Stellite Welding Electrode

- Stellite Alloy Welding Rod

- Hard Surfacing Rods

Technical Parameters:

| Technical Parameters |

Value |

| Magnetic Properties |

Non-magnetic |

| Elongation |

20-30% |

| Hardness |

HRC 50-60 |

| Heat Resistance |

Up to 1000°C |

| Corrosion Resistance |

Excellent |

| Surface Finish |

Smooth |

| Applications |

Hardfacing, Wear-resistant Components, High Temperature Components |

| Tensile Strength |

1000-1200 MPa |

| Material |

Cobalt Chrome Alloy |

| Melting Point |

1300-1400°C |

| Special Features |

Designed for hard facing electrodes and hard facing tig rod, compatible with stellite rod |

Applications:

Cobalt Chrome Alloy - The Ultimate Solution for Hardfacing and High Temperature Components

Cobalt Chrome Alloy, also known as Stellite, is a high-performance alloy that is widely used in various industries for its exceptional hardness, wear resistance, and high temperature capabilities. With a hardness of HRC 50-60, smooth surface finish, and 20% IACS electrical conductivity, this alloy is the go-to choice for hardfacing, wear-resistant components, and high temperature components.

What is Cobalt Chrome Alloy?

Cobalt Chrome Alloy is a type of alloy that is made up of cobalt, chromium, and other elements such as tungsten, nickel, and carbon. It is known for its excellent combination of high strength, hardness, and corrosion resistance, making it suitable for use in harsh environments.

Hardfacing Applications

Hardfacing is a process of applying a protective layer of material to the surface of a component to improve its wear resistance and extend its lifespan. Cobalt Chrome Alloy is widely used in hardfacing applications, especially in the oil and gas industry, where components are subjected to extreme wear and corrosion. The alloy is available in different forms such as stellite welding electrode, hard surfacing rods, and stellite tig rod, making it easy to use for various hardfacing needs.

Wear-Resistant Components

Thanks to its exceptional hardness and wear resistance, Cobalt Chrome Alloy is widely used in the manufacturing of wear-resistant components such as pump parts, valve seats, and cutting tools. These components are constantly exposed to abrasive and corrosive environments, and the use of this alloy ensures extended service life and reduced maintenance costs.

High Temperature Components

With a melting point of 1300-1400°C, Cobalt Chrome Alloy is perfect for use in high temperature components such as gas turbine parts, furnace parts, and aerospace components. The alloy can withstand high temperatures without losing its strength and hardness, making it a reliable choice for critical applications.

Cobalt Chrome Alloy Powder

In addition to its various forms mentioned above, Cobalt Chrome Alloy is also available in powder form, making it suitable for use in 3D printing and other additive manufacturing processes. The powder can be used to produce complex and high precision components, making it a favorite among industries such as automotive, aerospace, and medical.

In Conclusion

Cobalt Chrome Alloy is a versatile and high-performance alloy that finds its applications in various industries. Its exceptional hardness, smooth surface finish, and high temperature capabilities make it the ultimate solution for hardfacing, wear-resistant components, and high temperature components. With its various forms such as stellite welding electrode, hard surfacing rods, stellite tig rod, and cobalt chrome alloy powder, this alloy offers a wide range of options for different manufacturing needs.

So, whether you are looking to extend the lifespan of your components, improve their wear resistance, or produce high precision parts, Cobalt Chrome Alloy is the answer.

Support and Services:

Cobalt Chrome Alloy Technical Support & Service

Thank you for choosing Cobalt Chrome Alloy as your material of choice. Our dedicated technical support team is here to provide you with assistance and guidance throughout your product's lifecycle.

Technical Support

Our technical support team is available to answer any questions you may have regarding the properties and applications of Cobalt Chrome Alloy. We can provide you with detailed specifications, material data sheets, and assistance with material selection for your specific needs.

If you encounter any issues or challenges with using Cobalt Chrome Alloy, our team is here to help troubleshoot and find a solution. We also offer on-site support and training for your team, if necessary.

Quality Assurance

At Cobalt Chrome Alloy, quality is our top priority. Our products undergo rigorous testing and inspection to ensure they meet the highest standards. Our quality assurance team is committed to providing you with the best products and services possible.

Customization & Consultation

We understand that every project and application is unique. That's why we offer customization services for Cobalt Chrome Alloy to meet your specific requirements. Our team of experts can also provide consultation on material selection and design to optimize the performance of your product.

Ordering & Delivery

Our ordering process is quick and easy. Simply contact our sales team and they will guide you through the ordering process. We offer fast and reliable delivery options to ensure you receive your Cobalt Chrome Alloy in a timely manner.

After-Sales Service

We value your satisfaction and want to ensure that you are completely satisfied with our products and services. Our after-sales service team is available to assist you with any additional needs or concerns you may have.

Thank you for choosing Cobalt Chrome Alloy. We look forward to providing you with exceptional technical support and services for all your future projects.

Packing and Shipping:

Cobalt Chrome Alloy Packaging and Shipping

Packaging

Our Cobalt Chrome Alloy products are carefully packaged to ensure safe delivery to our customers. Each product is individually wrapped and packed in sturdy cardboard boxes to prevent damage during transit.

We also offer customized packaging options to meet the specific needs of our customers. Please contact us for more information.

Shipping

We offer various shipping options to accommodate the needs of our customers. Our products can be shipped by air, sea, or land, depending on the destination and urgency of the order.

We work with reputable shipping companies to ensure timely and reliable delivery of our products. Customers can also arrange their own shipping if preferred.

For international orders, please note that additional customs fees and taxes may apply. We recommend checking with your local authorities for more information.

For any questions or concerns regarding packaging and shipping, please don't hesitate to contact us. We are committed to providing the best service and products to our customers.

FAQ:

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!