Product Description:

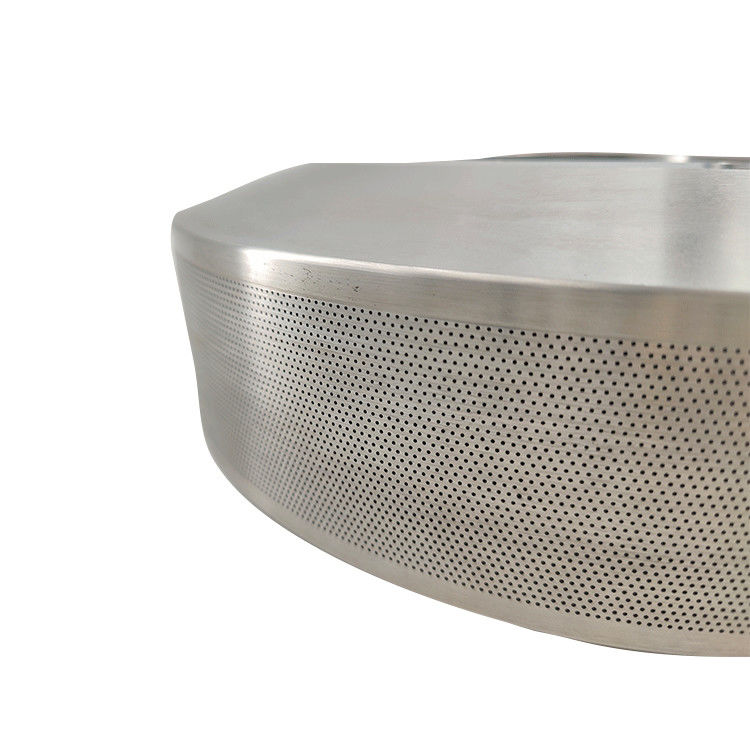

Cobalt-based alloys are renowned for their high-temperature strength, exceptional wear and corrosion resistance, and ability to retain hardness at elevated temperatures. Our Cobalt Alloy Castings, particularly the Cobalt Centrifuge Disc Castings, are engineered to meet the rigorous demands of various industrial applications. These castings are crafted with precision to ensure superior performance and longevity, catering to sectors where reliability under extreme conditions is paramount.

The Cobalt Based Centrifuge Disc Castings we offer are designed for high-performance environments, where components are subjected to intense forces and corrosive substances. With an elongation range of 10-15%, these castings exhibit a remarkable balance of ductility and strength, allowing them to withstand significant deformation before failure. This level of elongation is especially critical in applications where the castings may be exposed to impact or variable loads that can cause materials to stretch or bend.

The corrosion resistance of our Cobalt Centrifuge Disc Castings is excellent, ensuring that the components maintain their integrity even when exposed to harsh chemical environments. This resistance to corrosion is an essential attribute for industries that process corrosive substances, as it helps to minimize maintenance costs, prevent product contamination, and extend the service life of the castings.

With a diameter specification of 300mm/305mm, these Cobalt Centrifuge Disc Castings are suitable for a wide range of centrifuge machines. The precise diameter ensures a perfect fit within the equipment, contributing to the efficient and smooth operation of the centrifuge. The dimensional accuracy of the castings is critical for maintaining balance and reducing vibration, which can lead to wear and tear on other components.

One of the standout characteristics of our Cobalt Alloy Castings is their yield strength, which ranges from 800 to 1000 MPa. This high yield strength indicates that the castings can bear substantial loads without undergoing permanent deformation. This property is essential for applications that require the castings to support heavy weights or to endure high-stress conditions without compromising their structural integrity.

The melting point of our Cobalt Centrifuge Disc Casting alloys is between 1300-1400°C, which allows these materials to perform reliably in high-temperature applications. This high melting point is indicative of the alloy's ability to maintain its mechanical properties at elevated temperatures, making it an ideal choice for environments where thermal exposure is a concern, such as jet engines, gas turbines, and industrial furnaces.

In conclusion, our Cobalt Alloy Castings, particularly the Cobalt Based Centrifuge Disc Castings, are a testament to the advances in metallurgical engineering. They are not only tailored to withstand the harsh conditions of today's industrial applications but are also designed to deliver exceptional performance. The combination of elongation, corrosion resistance, precise diameter, yield strength, and high melting point makes these castings an invaluable component for industries that cannot afford to compromise on quality and reliability. Whether for use in chemical processing, aerospace, or energy generation, our Cobalt Centrifuge Disc Castings stand as a benchmark for durability and excellence in high-performance alloy castings.

Features:

- Product Name: Cobalt Alloy Castings

- Application: Industrial Machinery

- Wear Resistance: High

- Hardness: HRC 40-45

- Shape: Round

- Tensile Strength: 1000-1200 MPa

- Cobalt Centrifuge Disc Casting

- Cobalt Based Centrifuge Disc Castings

Technical Parameters:

| Attribute |

Value |

| Tensile Strength |

1000-1200 MPa |

| Shape |

Round |

| Elongation |

10-15% |

| Material |

Cobalt Alloy |

| Yield Strength |

800-1000 MPa |

| Heat Resistance |

High |

| Hardness |

HRC 40-45 |

| Corrosion Resistance |

Excellent |

| Density |

8.5-9.5 g/cm 3 |

| Wear Resistance |

High |

Applications:

Cobalt alloy castings, particularly Cobalt Centrifuge Disc Casting, are highly specialized products that offer superior performance in a variety of demanding applications. With a density ranging between 8.5-9.5 g/cm3, these castings are designed to provide exceptional wear resistance and strength, making them ideal for scenarios where high tensile strength (1000-1200 MPa) and durability are critical. The round shape and specific diameter of 300mm/305mm ensure that they fit perfectly in corresponding machinery and equipment.

One of the primary applications for Cobalt Based Centrifuge Disc Castings is in the aerospace industry. The high tensile strength of the cobalt alloy makes it suitable for components that are subject to intense forces and high temperatures, such as in jet engines and turbine blades. The ability to withstand such extreme conditions without deformation or failure makes cobalt alloy castings indispensable in aircraft design and maintenance.

In the medical field, Cobalt Centrifuge Disc Castings are used in medical imaging equipment and in devices that require precision like centrifuges used for blood separation. The non-reactive nature of cobalt alloys ensures that they can be used in environments where hygiene and corrosion resistance are paramount. Their high density provides the necessary mass for stabilization and vibration dampening in these sensitive applications.

The chemical industry also relies on Cobalt Centrifuge Disc Castings due to their excellent corrosion resistance. Equipment used for processing chemicals, such as pumps and valves, benefits from the use of cobalt alloy castings, as they maintain their integrity even in the presence of aggressive substances. This attribute ensures a longer service life and reduced maintenance costs for industrial chemical processing equipment.

Furthermore, the energy sector, including oil and gas exploration and production, finds Cobalt Based Centrifuge Disc Castings useful in drilling equipment. The cobalt alloy's ability to withstand abrasive environments helps in reducing wear and tear on drill bits and other components that come into contact with harsh substances, thereby enhancing efficiency and reducing downtime.

In summary, Cobalt Centrifuge Disc Casting is a versatile product with applications that span across various industries, from aerospace to medical to chemical processing. The unique properties of cobalt alloy, such as high tensile strength, corrosion resistance, and exceptional wear resistance, make it an ideal choice for scenarios that require materials to perform reliably under extreme conditions. The round shape and standardized diameter ensure ease of integration into existing systems, highlighting the product's adaptability and the broad range of potential applications.

Support and Services:

Our Cobalt Alloy Castings come with comprehensive technical support and services designed to ensure that you get the most out of our products. Our expert team is dedicated to providing you with top-notch assistance throughout the lifecycle of your castings. Our services include product installation guidance, troubleshooting support, maintenance recommendations, and performance optimization tips. We are committed to delivering quality and reliability in every casting, backed by our extensive knowledge and experience in cobalt alloy applications. Please consult our user manual for detailed instructions and best practices to maximize the performance and longevity of your castings. For further assistance, our customer service portal offers a wealth of resources including FAQs, technical documents, and case studies to help address your needs.

Packing and Shipping:

The Cobalt Alloy Castings are meticulously packaged to ensure their integrity during shipping. Each casting is individually wrapped in a protective padding material to prevent any scratches or impact damage. The padded castings are then securely placed in sturdy, custom-fitted crates, which provide additional protection and prevent movement during transit. We use moisture-absorbing packets inside the packaging to protect against corrosion from humidity and other environmental factors. All crates are clearly labeled with handling instructions and product information to facilitate safe and efficient transportation.

Before dispatch, all packages undergo a thorough inspection to guarantee they meet our strict quality and safety standards. Our shipping partners are carefully selected for their reliability and experience in handling industrial components. We provide tracking information for every shipment, allowing you to monitor the progress of your delivery and plan accordingly. Our aim is to ensure that your Cobalt Alloy Castings arrive at your facility in pristine condition, ready for use.

FAQ:

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!