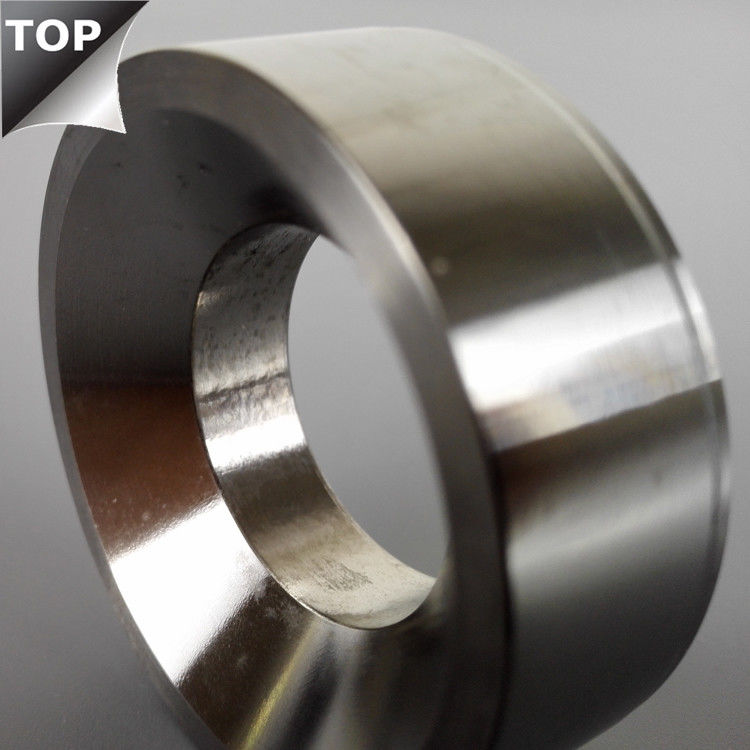

Cobalt Chrome Alloy hot extrusion die is designed to extrude the copper , aluminum bars , rods and other profiled

parts ,the points is in high temperature environment . the prcess must be hot extrusion . The Cobalt Chrome Alloy

material will help you to solve he high temperature and wear resistance issue . for more detail please

check as below .

(1.)cobalt alloy is a range of cobalt-chromium alloys designed for wear resistance.

(2)It is a completely non-magnetic and corrosion , resistant cobalt alloy.

(3)There are a number of Cobalt Chrome Alloys, with various compositions optimised for different uses.

(4)Some are formulated to maximize combinations of wear resistance, corrosion resistance,

or ability to withstand extreme temperatures.

Chemical compositions and properties (%)

| Brand |

C |

Mn |

Si |

Cr |

Ni |

Mo |

W |

Co |

Fe |

P |

S |

Density

(g/cm3)

|

Hardness

(HRC)

|

| ST 3 |

2.0-2.7 |

1.0 |

1.0 |

29-33 |

3.0 |

|

11-14 |

Bal. |

3.0 |

≤0.03 |

≤0.03 |

8.55 |

51-55 |

| ST 6 |

0.9-1.4 |

1.0 |

1.5 |

27-31 |

3.0 |

1.5 |

3.5-5.5 |

Bal. |

3.0 |

≤0.03 |

≤0.03 |

8.35 |

38-44 |

Production process

1. Powder metallurgy process

A. Better metallurgical structure, better strength

B. Various types of automatic pressing machines from 3 tons to 630 tons. The ordered profiles can be very flexible.

2. Investment casting process

Different volume of furnaces, the order quantity can be very flexible.

3. Machining

CNC, lathing, drilling, milling, grinding, wire cutting, polishing

Advantages

1. Excellent wear resistance , corrosion resistance and high temperature resistance

2. Easy to machine

Drawings &Pictures

Our producing process is :

Dosing ------Mixture powders-----crushing ------Pressing ------Sintering------Grinding ------Inspection------Products-----Package

Company activity:

Shenyang Top New Material Co., Ltd owns its advantages in the industrial metal materials area. The company specializes in the R&D, manufacturing and sales of investment casting and powder metallurgy components made of Cobalt Chrome alloy. Founded in Year 2001, SYTOP has 16 years producing experience and 10 years exporting experience. Our solid quality and integrity wins us a good name in our customers.

Our service

1.Drawing made and products design

Our professional engineer team supply drawing design service .

2.A entire process supervising

Our sales team will update the whole progress to you .

3.Good English communication and export service .

4.Quickly reply and provide professional solution to your project.

FAQ

|

Q1: What is the Warranty for the cobalt alloy products ?

>>> We own high precision grading machine to control geometry dimensions and apply ultra fine grain size substrate coated with high performance coatings to guarantee the lifetime of our products, which can satisfy every working condition.If any quality problems on our side occurred in this period , we will take on the shipping cost and replacement.

Q2: Do you provide free samples?

>>> Yes, usually we provide free samples for testing under the condition of freight paid by customer.

Q3: What is your minimum order requirement?

>>> We will indicate the MOQ for each item in the quotation sheet. We accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

Q4: What is the delivery time of your products?

>>> It depends on the inventory availability.If items needed are in stock, the delivery time would be within 8 work days, but if not the delivery time would be around 20 work days.

Q5: Can you manufacture carbide Special-shaped products?

>>> Yes, we can. We can produce both standard end mills and special tools. We can make them according to your drawings and samples.

Q6: May I have my order working schedule ?

>>> Yes, we will send working schedule of your order each week. We will inspect and test all merchandise in case of damaging and missing parts before shipment. The detailed inspection pictures of the order will be sent to you for your confirmation before delivery.

|

Your feedback is our best honor, please do not hesitate to give us your valuable feedback and we can let you feel more confident to our company and products.

Send your inquiry details right now !!!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!