Product Description:

Cobalt Chrome Alloy Product Overview

Cobalt chrome alloy is a highly versatile and durable material that is widely used in various industries, such as aerospace, medical, and marine. It is a combination of cobalt and chromium, with small amounts of other elements like tungsten, nickel, and molybdenum. This alloy is known for its exceptional properties, including excellent corrosion resistance, smooth surface finish, high hardness, and good electrical conductivity.

Surface Finish: Smooth

The surface finish of cobalt chrome alloy is smooth, making it ideal for applications that require a polished and sleek appearance. This makes it a popular choice for jewelry, watches, and other decorative items. Additionally, the smooth surface also helps in reducing friction and wear, making it suitable for use in machinery and equipment.

Corrosion Resistance: Excellent

Cobalt chrome alloy has excellent corrosion resistance, making it suitable for use in harsh environments, such as marine and chemical industries. It can withstand exposure to corrosive chemicals, saltwater, and high temperatures, without losing its strength and properties. This makes it a reliable and long-lasting material for various applications.

Electrical Conductivity: 20% IACS

With an electrical conductivity of 20% IACS (International Annealed Copper Standard), cobalt chrome alloy is a good conductor of electricity. This makes it suitable for use in electrical and electronic components, such as connectors, switches, and contacts. It also has low electrical resistance, making it an efficient material for conducting electricity.

Hardness: HRC 50-60

Cobalt chrome alloy has a high hardness level, with a range of HRC 50-60 (Rockwell hardness scale). This makes it one of the hardest materials used in various industries. It can withstand heavy loads, high temperatures, and wear and tear, without getting deformed or damaged. This makes it a preferred choice for applications that require high strength and durability.

Density: 8.4 g/cm³

Cobalt chrome alloy has a density of 8.4 g/cm³, which is relatively high compared to other alloys. This makes it a heavy and sturdy material, suitable for use in applications where weight and strength are important factors. Its high density also makes it resistant to deformation and helps in maintaining its shape and properties under extreme conditions.

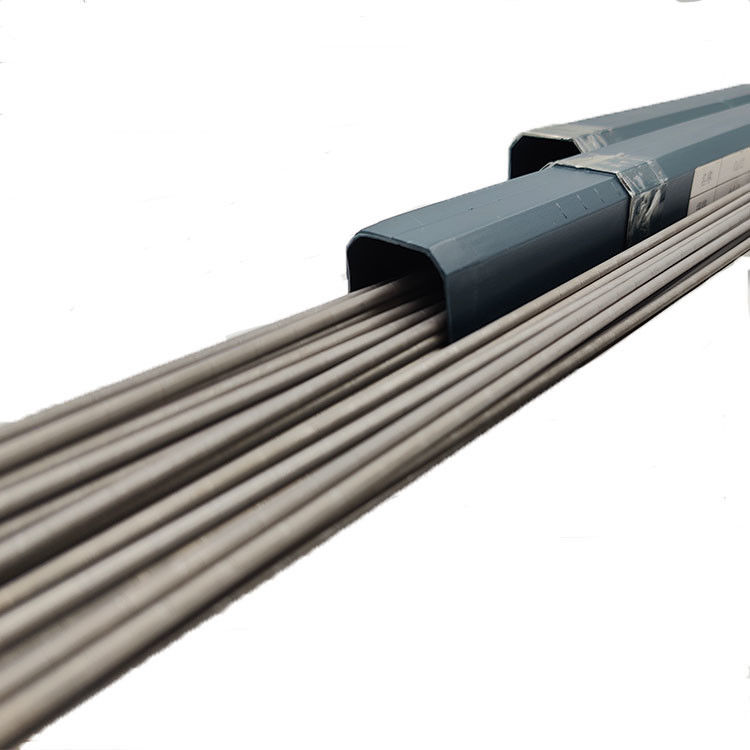

Welding Rod for Hardfacing

Cobalt chrome alloy is widely used as a welding rod for hardfacing applications. Its high hardness and wear resistance make it suitable for use in welding and repairing surfaces that are subject to high wear and impact. It can be used as a hard facing TIG rod or a hardfacing welding rod, providing a strong and durable layer of protection to the base material.

Hardfacing Electrode

Cobalt chrome alloy is also commonly used as a hardfacing electrode in welding processes. Its properties make it an ideal material for creating a protective layer on surfaces that are prone to wear, corrosion, and erosion. It can be used in various welding techniques, such as shielded metal arc welding (SMAW) and gas tungsten arc welding (GTAW), to provide a sturdy and wear-resistant coating.

In conclusion, cobalt chrome alloy is a highly versatile and reliable material that offers excellent corrosion resistance, smooth surface finish, good electrical conductivity, high hardness, and high density. Its unique properties make it a preferred choice for a wide range of applications, from decorative items to heavy-duty machinery. Whether used as a welding rod for hardfacing or a hardfacing electrode, cobalt chrome alloy provides a strong and durable solution for various industrial needs.

Features:

- Product Name: Cobalt Chrome Alloy

- Melting Point: 1300-1400°C

- Applications: Hardfacing, Wear-resistant Components, High Temperature Components

- Surface Finish: Smooth

- Elongation: 20-30%

- Electrical Conductivity: 20% IACS

- Hardfacing stick electrodes

- Hard surfacing rods

- Hard facing tig rod

Technical Parameters:

| Technical Parameters |

Values |

| Corrosion Resistance |

Excellent |

| Density |

8.4 g/cm³ |

| Melting Point |

1300-1400°C |

| Applications |

Hardfacing, Wear-resistant Components, High Temperature Components |

| Tensile Strength |

1000-1200 MPa |

| Material |

Cobalt Chrome Alloy |

| Coefficient Of Thermal Expansion |

12.5 μm/m·K |

| Surface Finish |

Smooth |

| Heat Resistance |

Up to 1000°C |

| Magnetic Properties |

Non-magnetic |

| Hard Face Welding Electrodes |

Available |

| Hard Facing Electrodes |

Available |

| Wear Plate |

Available |

| Wear Resistant Components |

Available |

| Cobalt Chrome Alloy |

Available |

| High Temperature Components |

Available |

Applications:

Cobalt Chrome Alloy Product Description

Introduction

The Cobalt Chrome Alloy, also known as CoCr alloy, is a type of high-performance material widely used in various industrial applications. This alloy is composed of cobalt and chromium, and it is known for its excellent hardness, corrosion resistance, and thermal expansion coefficient. These attributes make it a popular choice for a wide range of products, including hardfacing rods, hard facing tig rods, and other industrial products.

Product Attributes

| Attribute |

Description |

| Coefficient Of Thermal Expansion |

12.5 μm/m·K |

| Material |

Cobalt Chrome Alloy |

| Hardness |

HRC 50-60 |

| Elongation |

20-30% |

| Corrosion Resistance |

Excellent |

Application Areas and Scenarios

The Cobalt Chrome Alloy has a wide range of applications in various industries, thanks to its remarkable properties. Below are some of the common areas where this alloy is used:

Hardfacing is a welding process used to create a hard, wear-resistant surface on metal parts. The Cobalt Chrome Alloy, with its high hardness and excellent corrosion resistance, is an ideal choice for hardfacing rods. These rods are used in mining, construction, and other industries where heavy equipment is subjected to extreme wear and tear.

The hard facing tig rods are used in precision welding applications, where a high level of control and precision is required. The Cobalt Chrome Alloy's thermal expansion coefficient makes it a perfect match for hard facing tig rods, ensuring minimal distortion during welding and precise results. These rods are commonly used in the aerospace, automotive, and medical industries.

- Hardfacing Rods:

- Hard Facing Tig Rods:

Conclusion

The Cobalt Chrome Alloy is a versatile and high-performance material that finds its application in various industries. Its exceptional properties, including a low coefficient of thermal expansion, excellent hardness, and corrosion resistance, make it a popular choice for hardfacing rods, hard facing tig rods, and other industrial products. With its wide range of applications, this alloy is a crucial element in the manufacturing and maintenance of heavy equipment and precision components.

Support and Services:

Technical Support and Services for Cobalt Chrome Alloy

Cobalt Chrome Alloy is a high-performance material known for its exceptional strength, corrosion resistance, and biocompatibility. As a leading provider of Cobalt Chrome Alloy products, we are committed to providing top-notch technical support and services to ensure the best performance and satisfaction for our customers.

Technical Support

Our team of experienced engineers and technicians are dedicated to providing timely and effective technical support to our customers. We offer troubleshooting assistance, material selection guidance, and process optimization recommendations to help you achieve the desired results with Cobalt Chrome Alloy. We also provide on-site support and conduct training sessions to help our customers understand the properties and applications of Cobalt Chrome Alloy.

Customization Services

At Cobalt Chrome Alloy, we understand that every project and application is unique. That's why we offer a wide range of customization services to tailor our Cobalt Chrome Alloy products to your specific needs. From design and prototyping to precision machining and finishing, our team will work closely with you to provide customized solutions that meet your requirements.

Quality Assurance

We take pride in the quality of our Cobalt Chrome Alloy products and are committed to maintaining the highest standards. Our products undergo strict quality control processes and are tested for mechanical properties, corrosion resistance, and biocompatibility to ensure they meet industry standards. We also provide material certifications and documentation for traceability and quality assurance purposes.

After-Sales Service

Our commitment to our customers doesn't end with the sale. We offer comprehensive after-sales services to ensure your continued satisfaction with our Cobalt Chrome Alloy products. Our team is available to address any concerns or questions you may have and provide ongoing support to help you achieve the best results.

Thank you for choosing Cobalt Chrome Alloy. We are dedicated to providing top-notch technical support and services to help you succeed with our high-performance products. For more information or assistance, please contact us.

Packing and Shipping:

Packaging and Shipping of Cobalt Chrome Alloy

Cobalt Chrome Alloy is carefully packaged to ensure safe delivery to our customers. The packaging process is done with precision and attention to detail to protect the product from any damage during transportation.

Packaging Methods

There are two primary packaging methods used for Cobalt Chrome Alloy:

- Vacuum-sealed packaging: This method involves placing the product in a sealed plastic bag and removing all air from the bag before sealing. This ensures that the product remains free from any contamination and is protected from moisture and other external factors.

- Wooden crates: For larger quantities of Cobalt Chrome Alloy, we use wooden crates for packaging. These crates are sturdy and provide excellent protection during transportation.

Shipping

We offer various shipping options for our customers to choose from based on their location and urgency of delivery. Our team works closely with trusted shipping companies to ensure timely and secure delivery of our products.

The shipping process includes careful handling and loading of the packaged product onto trucks or containers. We also provide proper labeling and documentation to ensure a smooth shipping process.

We strive to deliver our products to our customers in the most efficient and cost-effective manner. Our packaging and shipping methods have been carefully designed to ensure that our customers receive their Cobalt Chrome Alloy in perfect condition.

FAQ:

- Q:What is the melting point of Cobalt Chrome Alloy?

- A:The melting point of Cobalt Chrome Alloy is approximately 1,480°C (2,700°F).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!