Product Description:

Features:

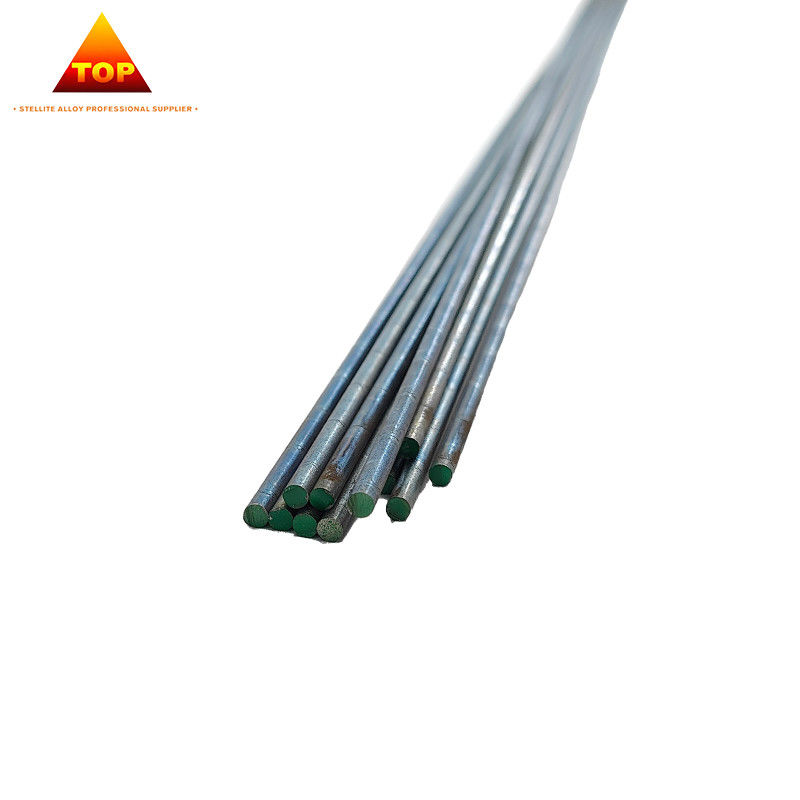

- Product Name: Cobalt Chrome Alloy

- Corrosion Resistance: Excellent

- Wear Resistance: High

- Heat Resistance: Up to 1000°C

- Magnetic Properties: Non-magnetic

- Density: 8.4 g/cm³

- Hardfacing Electrodes Welding Rod

- AWS A5.21 Welding Electrode

- Hard Surfacing Rods

Technical Parameters:

| Technical Parameters | Cobalt Chrome Alloy |

|---|

| Hardness | HRC 50-60 |

| Electrical Conductivity | 20% IACS |

| Coefficient Of Thermal Expansion | 12.5 μm/m·K |

| Elongation | 20-30% |

| Wear Resistance | High |

| Melting Point | 1300-1400°C |

| Surface Finish | Smooth |

| Tensile Strength | 1000-1200 MPa |

| Applications | Hardfacing, Wear-resistant Components, High Temperature Components |

| Magnetic Properties | Non-magnetic |

| Keywords | welding rods, Hard Facing Tig Rod, Hardfacing Stick Electrodes |

Applications:

Cobalt Chrome Alloy

Cobalt Chrome Alloy, also known as Cobalt-Chromium-Molybdenum (CoCrMo), is a high-performance alloy that is widely used in various industries due to its exceptional properties. This alloy is composed of cobalt, chromium, and molybdenum, making it highly resistant to wear, corrosion, and high temperatures. It is also known for its high strength, durability, and excellent electrical conductivity.

Electrical Conductivity

The electrical conductivity of Cobalt Chrome Alloy is 20% IACS (International Annealed Copper Standard). This makes it an ideal choice for applications that require good electrical conductivity, such as in electrical components, power generation, and electronic devices. The high electrical conductivity of this alloy allows for efficient conduction of electricity, reducing energy loss and increasing overall performance.

Tensile Strength

The tensile strength of Cobalt Chrome Alloy is between 1000-1200 MPa (Megapascals). This high tensile strength makes it suitable for use in high-stress applications, such as in aerospace, automotive, and oil and gas industries. The alloy's ability to withstand tension and resist deformation under heavy loads makes it a preferred choice for critical components that require high strength and reliability.

Surface Finish

The surface finish of Cobalt Chrome Alloy is smooth, making it ideal for applications that require a polished and aesthetically pleasing appearance. This alloy can be easily machined, polished, and plated to achieve a smooth and shiny finish. Its smooth surface also makes it resistant to corrosion and wear, making it a durable choice for applications in harsh environments.

Density

The density of Cobalt Chrome Alloy is 8.4 g/cm³ (grams per cubic centimeter), making it a relatively lightweight material. This makes it a popular choice for applications that require high strength and durability without adding too much weight, such as in aerospace and automotive industries. The low density of this alloy also makes it easy to handle and transport, reducing overall production costs.

Elongation

The elongation of Cobalt Chrome Alloy is between 20-30%, which means it can withstand a certain level of deformation before breaking. This property makes it suitable for applications that require flexibility and resilience, such as in medical implants, dental prosthetics, and precision instruments. The alloy's ability to elongate and return to its original shape without breaking makes it a reliable choice for critical applications.

Applications

The unique properties of Cobalt Chrome Alloy make it suitable for various applications in various industries. Some of its typical applications include:

- Hardfacing Stick Electrodes: Cobalt Chrome Alloy is often used as a coating material in hardfacing stick electrodes. These electrodes are used for welding and repairing worn-out or damaged surfaces, providing a hard and wear-resistant coating that extends the material's lifespan.

- Hard-Facing Electrodes: Cobalt Chrome Alloy's high strength and wear resistance make it an ideal choice for hard-facing electrodes. These electrodes create a hard surface on metal parts subjected to heavy wear and tear, such as in mining, construction, and agricultural equipment.

- AWS A5.21 Welding Electrode: The welding electrode, also known as the welding rod, is another popular application of Cobalt Chrome Alloy. These electrodes are used in welding and repairing high-temperature and high-stress parts, such as in gas turbines, petrochemical plants, and power plants.

Overall, Cobalt Chrome Alloy is a versatile and high-performance material used in various applications where strength, durability, and electrical conductivity are critical. Its unique properties make it a preferred choice for industries that require reliable and long-lasting components.

Support and Services:

Cobalt Chrome Alloy Technical Support and Services

Our team of experts is dedicated to providing the highest level of technical support and services for our Cobalt Chrome Alloy products.

Technical Support

Our technical support team is available to assist with any inquiries or issues related to our Cobalt Chrome Alloy products. We offer remote troubleshooting, on-site visits, and phone consultations to ensure that our customers receive timely and effective support.

Customized Solutions

We understand that each customer has unique requirements and specifications. That's why we offer customized solutions to meet your specific needs. Our experienced engineers will work closely with you to design and manufacture Cobalt Chrome Alloy products that meet your exact requirements.

Quality Assurance

Our Cobalt Chrome Alloy products undergo rigorous quality control procedures to ensure their performance and reliability. We adhere to international standards and regulations to guarantee the highest quality products for our customers.

Training and Education

We provide training and education services to help our customers understand the properties and capabilities of Cobalt Chrome Alloy. Our training programs cover topics such as material properties, processing techniques, and product applications.

After-Sales Services

Our commitment to our customers doesn't end with the sale of our products. We offer comprehensive after-sales services, including maintenance, repair, and replacement services to ensure the long-term performance of our Cobalt Chrome Alloy products.

Trust our team of experts to provide you with the best technical support and services for your Cobalt Chrome Alloy needs. Contact us today to learn more.

Packing and Shipping:

Packaging and Shipping of Cobalt Chrome Alloy

Cobalt Chrome Alloy is packaged and shipped by our experienced team to ensure safe and secure delivery to our customers. The following steps are taken to ensure the quality and integrity of the product during packaging and shipping:

- The alloy is carefully inspected and packaged in airtight containers to prevent contamination.

- Each container is labeled with the product name, batch number, and date of production for easy identification.

- The containers are then placed in sturdy boxes and sealed for shipping.

- We use reliable and reputable shipping companies to ensure timely and efficient delivery.

- For international shipments, all necessary customs documentation and certifications are provided.

- We also offer special packaging and shipping options for bulk orders or delicate products.

Our top priority is to ensure that our customers receive their Cobalt Chrome Alloy in perfect condition. If there are any concerns or issues with the packaging or shipping, please contact us immediately and we will work to resolve the issue.

FAQ:

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!